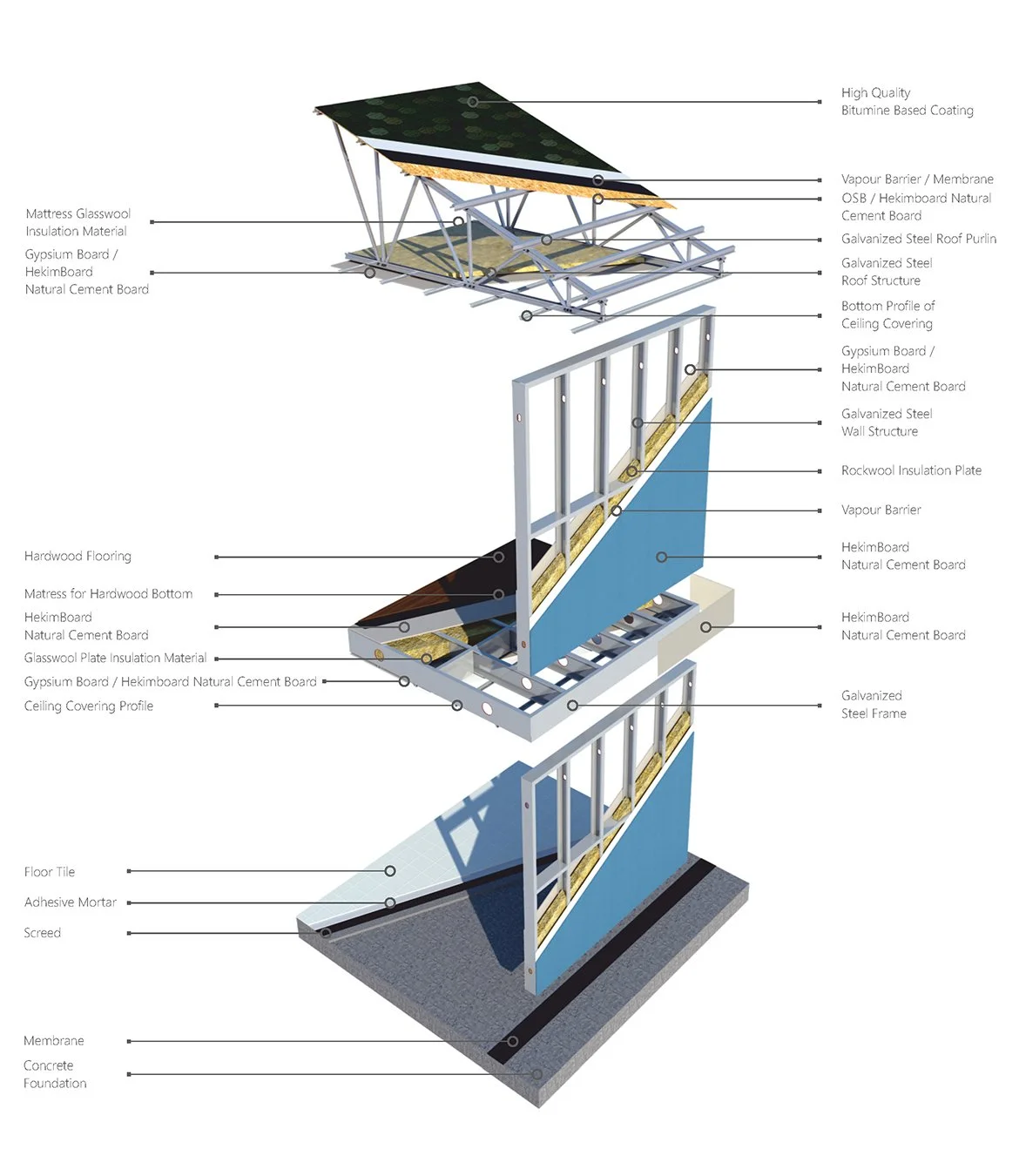

Patented Light Steel Panel Formula

The near-zero energy assembled light steel truss wall structure offers significant benefits across various aspects, including safety, health, labor efficiency, precision, energy efficiency, and sustainability. Below is a detailed and professional breakdown of its key advantages:

1. Safety and Durability

Fire Resistance: The structure is made from fire-retardant materials (Class A flame retardant), providing a high level of protection against fire hazards.

Seismic and Weather Resistance: Designed to withstand earthquakes up to Level 9 (Basic seismic acceleration 0.4g), hurricanes, and other extreme weather conditions. The structure is shockproof, anti-impact, and features nailable anchor bolts for enhanced stability. It is also resistant to snow impacts (1.55 kN/㎡) and wind speeds up to 130 miles per hour.

Structural Robustness: With a density 1.5 times greater than wood, the light steel framework is exceptionally resilient, crack-resistant, and earthquake-resistant. The structure offers up to 15 times more airtightness than conventional stick-built constructions. It can resist vertical forces of up to 6500 kg and horizontal forces of up to 1500 kg.

Longevity: The building offers an impressive lifespan of up to 100 years with minimal maintenance. The materials are resistant to termites, insects, moisture, mold, and corrosion, drastically reducing long-term maintenance costs.

2. Health and Comfort

Climate Control: The near-zero energy wall structure utilizes advanced insulation technology, maintaining a consistent indoor temperature and humidity. This ensures warmth in winter and coolness in summer, contributing to enhanced comfort. The energy-efficient design minimizes heat loss through windows and the ground, achieving near-zero energy consumption. Insulation values (R=34 for pure panels, R=45 for finished walls) outperform traditional brick walls (R=8).

Noise and Air Quality: The structure is highly effective at isolating external noise, reducing vibrations, and providing soundproofing, achieving a voice insulation rating of 45 dB.

Ventilation: A fresh air ventilation system ensures continuous airflow, maintaining a healthy and comfortable indoor environment. The integrated fresh air system supports natural ventilation, ensuring an air exchange rate of >15% to promote freshness and healthy air indoors. The air quality is also optimized by eliminating harmful effects from PM2.5.

3. Labor Efficiency and Cost Reduction

Prefabricated Components: The system includes pre-engineered prefabricated wall panels, floors, ceilings, and pre-installed plumbing, electrical outlets, and finishes, reducing labor costs by over 50%.

Faster Construction: Prefabrication accelerates on-site assembly, reducing the construction time by over 75%. The modular "build blocks" assembly approach streamlines the process, making it highly efficient.

Cost-Effectiveness: The prefabricated system reduces the need for extensive on-site labor and heavy machinery. Over 90% of the work typically performed on-site is replaced by factory-produced components, leading to substantial savings in both labor and equipment costs.

4. High Precision and Space Optimization

Space Utilization: The design of the near-zero energy wall structure maximizes usable floor space, increasing it by approximately 8-10% compared to traditional construction methods. This higher resource utilization leads to better value and greater functional space, including the ability to reduce the size of HVAC equipment.

Environmental Harmony: The structure is designed with sustainability in mind, incorporating eco-friendly materials that minimize environmental impact. The result is an aesthetically pleasing and environmentally responsible building.

5. Energy Efficiency and Sustainability

Ultra-Low Energy Consumption: The near-zero energy wall structure is highly energy-efficient, reducing heating and cooling costs by up to 82% compared to conventional homes. The overall energy-saving potential of the structure can reach up to 92%, making it significantly more energy-efficient than traditional buildings.

Energy Savings: The system effectively preserves heat and minimizes energy consumption by 85-92%, which not only reduces operational costs but also supports environmental conservation efforts. For example, a 1500 sq. ft. house using the new material only requires 7,560 kWh of energy, compared to 15,120 kWh required by traditional materials. This represents a significant reduction in energy consumption and operational costs, with the new material consuming roughly 1/9th the energy of traditional building methods.

6. Green Construction and Environmental Impact

Asbestos-Free and Non-Toxic: All materials used in the construction are 100% asbestos-free, and the indoor environment is free of formaldehyde, ensuring a safe and healthy living space.

Reduction in Waste and Pollution: Traditional buildings generate substantial construction waste, often as high as 200 kg per square meter. This contributes significantly to urban landfill volumes. In contrast, the system minimizes construction waste and eliminates water and dust pollution. It also reduces smog and PM2.5 levels, promoting cleaner air in urban areas.