Engineered Prefabricated Light Steel Truss Wall System

The assembled light steel truss wall structure system is an advanced prefabricated building technology that integrates digital design, modularization, and industrialized construction. By utilizing Building Information Modeling (BIM), building components such as wall panels, floor slabs, rafters, stairs, doors, and windows are digitally designed and input into factory control systems. These components are then precisely prefabricated on automated production lines, each with a unique identification number, enabling high-efficiency on-site assembly.

This structural system eliminates the need for conventional concrete frames, on-site slab pouring, and heavy lifting equipment. It achieves a high assembly rate and offers a simplified construction process. The system integrates load-bearing, insulation, and wall functions into a single unit and is ideal for buildings within a certain height range.

The system represents an innovative evolution in structural mechanics, combining modular construction with passive energy-saving technologies. It provides a holistic solution for sustainable, cost-effective, and rapid construction.

This innovative prefabricated wall system offers a sustainable, high-performance, and construction-efficient solution that addresses modern building needs with minimal environmental impact and maximum long-term durability.

PBP: Prefabricated Building Panels

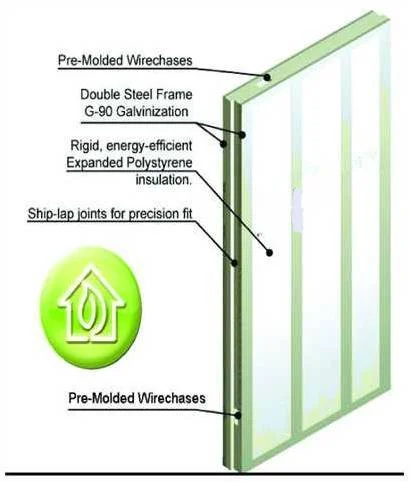

PBP (Pre-engineered Building Panels) are lightweight, cold-formed steel panels combined with Expanded Polystyrene (EPS), forming a Structural Insulated Panel (SIP) system.

Proven SIP technology with over 30 years of successful global application.

Suitable for internal and external walls, floors, and roofs, replacing traditional materials like reinforced concrete, timber, and masonry.

Composed of a metal stud frame for structural strength and EPS core for insulation.

Skins and foam are bonded with structural adhesive through a lamination process, ensuring durability and integrity.

Fabricated off-site according to architectural specifications and shipped for quick on-site installation.

Simple to finish post-installation, reducing labor and construction time.

Zero-Energy Steel Wall Technology

The zero-energy light steel wall system integrates light gauge steel framing and high-performance insulation into a 14 cm thick panel. Manufactured through autoclaving and precision machinery, this box-like panel design provides:

No thermal bridging, maximizing energy retention.

Excellent thermal insulation, anti-seismic and wind resistance capabilities.

High lateral, longitudinal, and shear load capacities.

Environmentally friendly materials, replacing wood with recyclable alternatives, minimizing resource consumption.